In today's highly competitive industrial equipment market, efficiency and control over the manufacturing process are essential for businesses of all sizes. To stay competitive and profitable, industrial equipment manufacturers need to optimize workflow, inventory management, production planning, and supply chain control. This is where manufacturing software comes into play. In this article, we will explore 12 compelling reasons why your industrial equipment business needs manufacturing software to thrive in the industry.

1. Streamline Business Processes Through Automation

Manufacturing software offers a centralized solution that streamlines all your business processes. With real-time data and a comprehensive overview of your entire manufacturing operation, you can effectively manage, monitor, and maintain your equipment, workstations, and workforce. By automating tasks and reducing dependency on manual processes, manufacturing software frees up your workforce to focus on core activities, minimizing errors, accelerating production processes, and improving profitability.

2. Optimize Inventory Management and Control

Efficient inventory management is crucial for industrial equipment manufacturers. Manufacturing software provides real-time insights into your inventory, from raw materials to finished goods. By setting up reorder points and tracking stock levels, you can avoid stockouts and optimize inventory movements. With features like multilevel bills of materials (BOMs) and subassemblies, you can easily manage and track components, ensuring precise costing and inventory control.

3. Enhance Production Planning and Scheduling

Precise production planning and scheduling are vital for industrial equipment manufacturers. Manufacturing software offers robust features that enable you to create a master production schedule, estimate requirements, and forecast production needs. By optimizing workflow, allocating resources efficiently, and automating production processes, you can minimize lead times, improve on-time delivery, and maximize overall productivity.

4. Improve Quality Control and Traceability

Maintaining high-quality standards is essential in the industrial equipment industry. Manufacturing software provides end-to-end traceability, allowing you to track and monitor each stage of your manufacturing process. By implementing quality control measures and ensuring compliance with industry regulations, you can deliver products that meet or exceed customer expectations.

5. Streamline Sales Order Management

Managing sales orders can be complex for industrial equipment manufacturers. Manufacturing software consolidates all your sales data into a single view, making it easier to process orders, manage customer requirements, and track order status. By integrating with your CRM system, you can streamline the sales order management process, improve customer satisfaction, and enhance overall sales performance.

6. Optimize Supply Chain Management

Efficient supply chain management is crucial for industrial equipment manufacturers. Manufacturing software helps optimize the inflow and outflow of your supply chain, ensuring timely procurement of materials, coordinating distribution channels, and centralizing purchasing locations. By gaining real-time visibility and control over your supply chain, you can reduce lead times, avoid bottlenecks, and improve overall operational efficiency.

7. Real-Time Data Insights for Informed Decision Making

Accurate and timely data is the foundation of informed decision-making. Manufacturing software collects and analyzes essential data in a shared server, providing real-time insights and visibility to your decision-making team. By having access to up-to-date information on production stats, inventory levels, and market demand, you can make informed decisions that drive growth and profitability for your industrial equipment business.

8. Enhance Collaboration and Communication

Effective collaboration and communication are vital for successful industrial equipment manufacturing. Manufacturing software facilitates seamless communication between different teams and departments, ensuring that everyone is on the same page. With features like real-time notifications, task assignments, and document sharing, you can improve teamwork, increase efficiency, and foster a culture of collaboration within your organization.

9. Boost Efficiency with Workflow Automation

Workflow automation is a key advantage of manufacturing software. By automating repetitive tasks, data entry, and document management, you can eliminate manual errors, save time, and increase overall efficiency. With automated workflows, you can streamline processes, reduce administrative burden, and focus on value-added activities that drive innovation and growth.

10. Comprehensive Reporting and Analytics

Manufacturing software provides robust reporting and analytics capabilities, allowing you to gain valuable insights into your business performance. With customizable dashboards and real-time reports, you can track key performance indicators (KPIs), measure productivity, analyze production costs, and identify areas for improvement. By leveraging data-driven insights, you can make informed decisions, optimize operations, and drive continuous improvement in your industrial equipment business.

11. Scalability and Flexibility for Business Growth

As your industrial equipment business grows, so do your operational needs. Manufacturing software offers scalability and flexibility to accommodate your changing requirements. Whether you need to add new products, expand production capacity, or enter new markets, manufacturing software can adapt to your evolving business needs, providing a solid foundation for future growth and success.

12. Stay Ahead of the Competition

In a highly competitive industrial equipment market, staying ahead of the competition is crucial. Manufacturing software gives you a competitive edge by optimizing your processes, improving productivity, enhancing customer satisfaction, and enabling faster response to market demands. By leveraging the power of technology, you can differentiate your industrial equipment business and maintain a strong position in the industry.

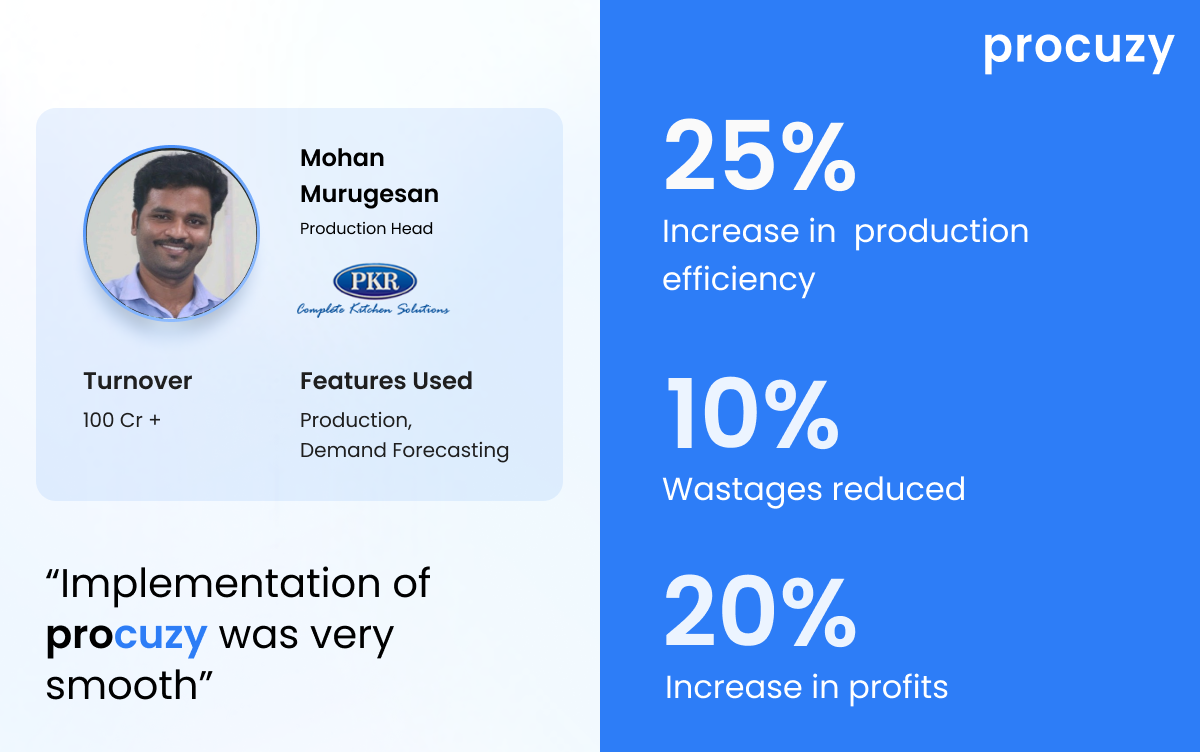

Procuzy's Impact: Empowering PKR Kitchens

PKR Equipments, a key player in kitchen industrial equipment, faced operational challenges until they joined forces with Procuzу's manufacturing software. Leveraging our centralized solution, PKR Equipments transformed their operations, streamlining processes, automating workflows, and gaining real-time insights.

Procuzу's features optimized inventory, improved production planning, and enforced rigorous quality control, resulting in heightened productivity and efficiency. Enhanced collaboration and communication within teams fueled innovation.

In a cutthroat market, Procuzу empowered PKR Equipments to outpace competitors by enhancing customer satisfaction and responding swiftly to market demands. This success story underscores how Procuzу's manufacturing software is a catalyst for growth and enduring success in the industrial equipment industry.

In conclusion, manufacturing software is a game-changer for industrial equipment manufacturers. With its ability to streamline business processes, optimize inventory management, enhance production planning, improve quality control, and provide real-time data insights, manufacturing software enables industrial equipment businesses to thrive in a competitive market. By adopting manufacturing software, you can boost efficiency, drive growth, and achieve long-term success in the industrial equipment industry.